공기기계로 불리는 기계는 전동기나 내연기관, 증기터어빈 등의 원동기로 피스톤이나 스크류, 로터, 치차 등 여러 형태의 액츄에이터를 구동하여 역학적인 에너지가 공기로 전달되도록 하는 구조를 가진다. 즉, 구동축에 가해지는 축 동력을 공기의 에너지로 변환 하는 기계라고 할 수 있다.

일반적으로 공기기계는 압력상승의 정도에 따라, 팬, 블로어 그리고 압축기로 분류되며, 다음과 같이 정의되고 있다.

팬(fan) : 토출압력이 10kPa 미만, 또는 압력비가 1.1 미만

송풍기(blower) : 토출압력이 10kPa 이상에서 0.1MPa 미만, 또는 압력비가 1.1 이상에서 2.0미만

압축기(compressor) : 토출압력이 0.1MPa 이상, 또는 압력비가 2.0 이상

공기압축기에는 다양한 종류가 있다. 이중 산업계에서 주로 사용되고 있는 형식은 왕복 동식, 회전식(스크류), 터보형 공기압축기 등 3가지 형태로 구분된다.

https://youtu.be/oy6X6cZWx2Y

Reciprocating Compressors

In reciprocating compressors, there will be a reciprocating piston moving axially in a cylinder and it reduces the volume of the air/ga and increases its pressure. Depending on the output pressure requirements, we can have single or multi-cylinder and single or multi-stage compressors.

The following image shows a simplified schematic of a reciprocating compressor. As the piston reciprocates back and forth, the suction and discharge valves control the suction of air/gas and compression of air/gas.

We can compare the working of a reciprocating compressor to that of a two-stroke engine. One revolution of the crank will complete both the suction and compression of the air/gas. The pressure difference between the cylinder and the inlet/outlet manifolds will cause the inlet (suction) and outlet (discharge) valves to open and close.

The inlet manifold will have a pressure approximately equal to the atmospheric pressure whereas the outlet manifold will have the pressure of the compressed air.

To increase the pressure of the air, reciprocating compressors come with multi-stage design. A typical single stage reciprocating compressor can deliver a pressure up to 6 bar. Two Stage (a type of multi-stage) Reciprocating Compressors are very popular in small garages and workshops and can produce pressure in the range of 5 – 35 bar. A three-stage compressor can deliver pressure in the range of 35 – 85 bar.

https://youtu.be/YOFrytC3IKQ

Rotary Compressors

The next type of air compressor is a Rotary Compressor. They are usually small in size and produce relatively less pressure. For example, a dentist’s vacuum system consists of a rotary compressor. There are two important types of rotary compressors: Screw and Vane.

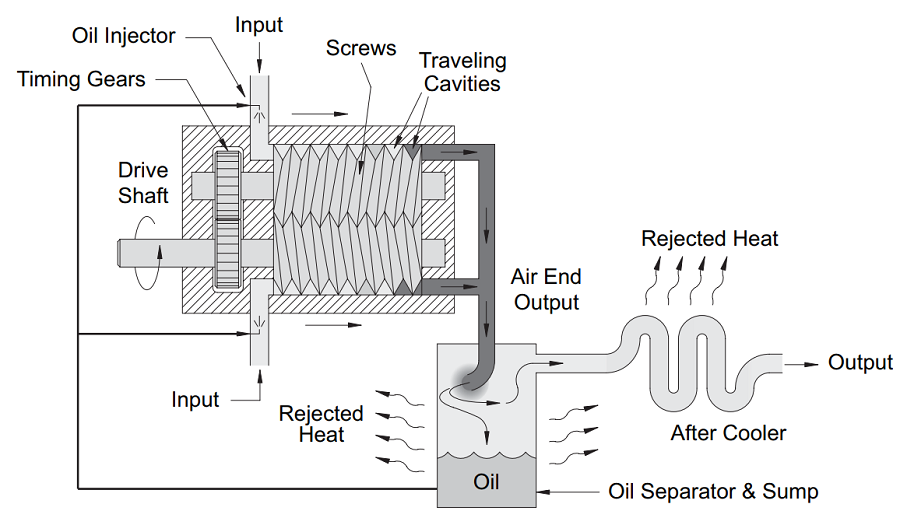

A Screw Compressor is an extremely popular type of air compressor in the industrial segment. You can find screw compressors with power range of 40 to 500HP. The name “Screw” Compressor comes from the fact that they have two different screws in the housing of the compressor. These screws have opposite threading i.e., one screw has a right-hand thread while the other has a left-hand thread.

https://youtu.be/fzn1XtkvKnI

Both these screws are meshed and synchronized using a timing gear set. A motor rotates the drive shaft, which in turn rotates the screws. As they rotate, they intake air and trap it in the cavities between the threads. This trapped air has high pressure.

Coming to Vane type rotary compressors, again there are two types: Fixed Vane and Multiple Vane. In fixed vane type rotary compressor, the axis of rotation of the roller’s rotating shaft lines up with the center of the cylinder but it is eccentric to the roller itself. This shaft creates suction and compression of air/gas.

In multiple vane type rotary compressor, the axis of rotation of the roller’s shaft lines up with the roller but it is eccentric to the cylinder. This creates a sliding vane and the rotor has several slots that align with the sliding vane.

When the compressor is running, the centrifugal forces of the rotor make the sliding vane to be held against the cylinder. A four-vane rotary compressor produces four compression strokes in one rotation.

Centrifugal Compressors

Next, we have dynamic compressor. Specifically, the centrifugal compressor is a type of Turbo Compressor. In this type of air compressors, the pressure of the air/gas increases as a result of conversion of angular momentum of a high-speed impeller into static pressure, which is imparted on the air/gas.

https://youtu.be/CDfMfpGOrz8

Centrifugal Compressors have a steady flow and hence they produce less noise and vibrations than reciprocating counterparts. The following image shows the impeller of a centrifugal compressor.

A low-pressure air enters through the center/eye of the impeller and passes through a flow passage consisting of several blades. These blades rotate at a very high speed and the air passing through these blades gain momentum and static pressure.

https://youtu.be/leosVYDGb-Q

Axial Flow Compressors

Another type of turbo compressor is an Axial Flow Compressor. In this type, the air/gas flows in parallel to the axis of the machine. Axial Compressors consists of several stages of rotor and stator blades.

They are very large devices and operate over 1000hp. The following image shows an industrial 5-stage axial flow compressor.

All the rotors are connected to a common drive shaft but each set of rotors is separated by a set of stators.

https://youtu.be/Il27VvHu-s0