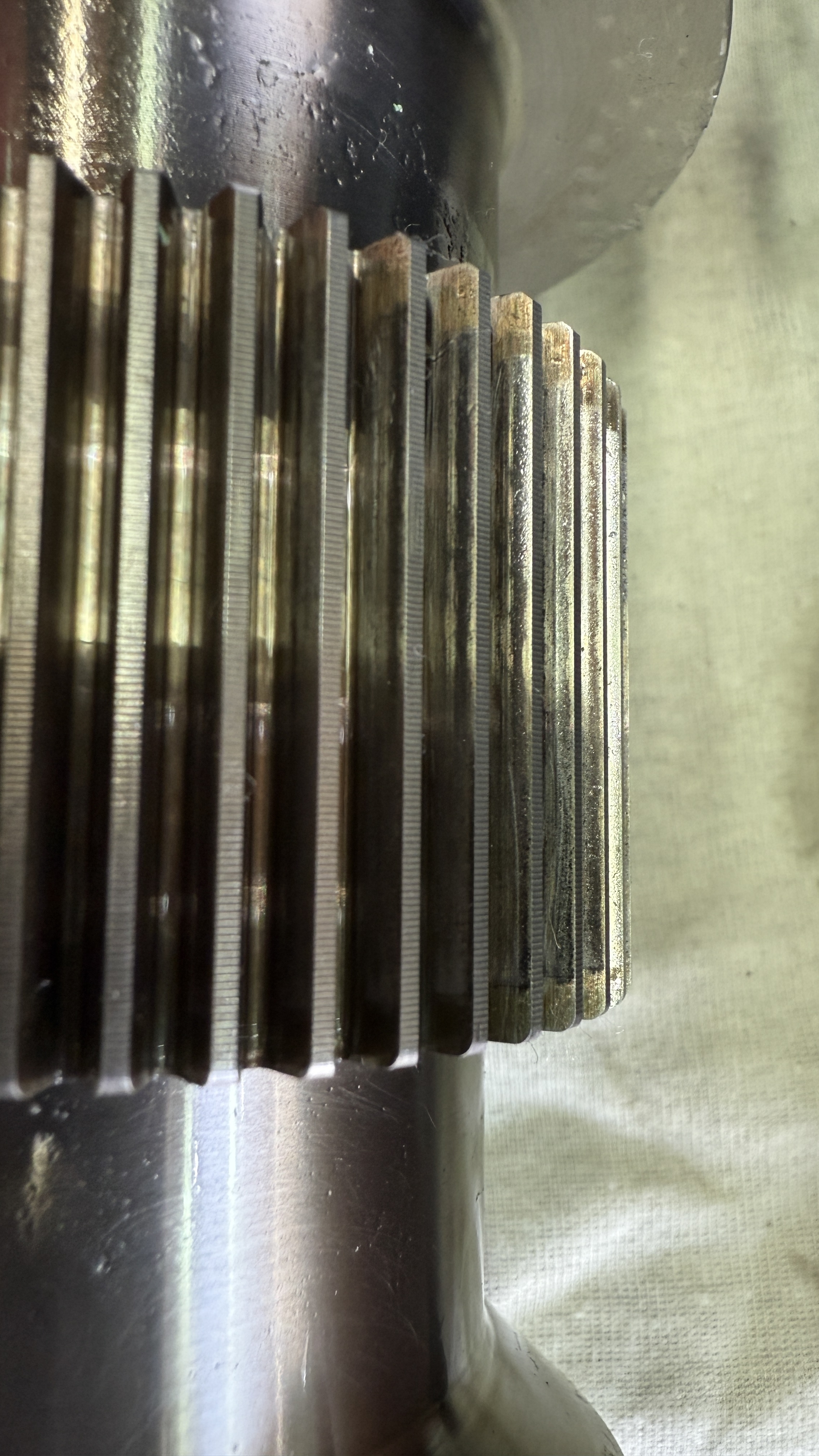

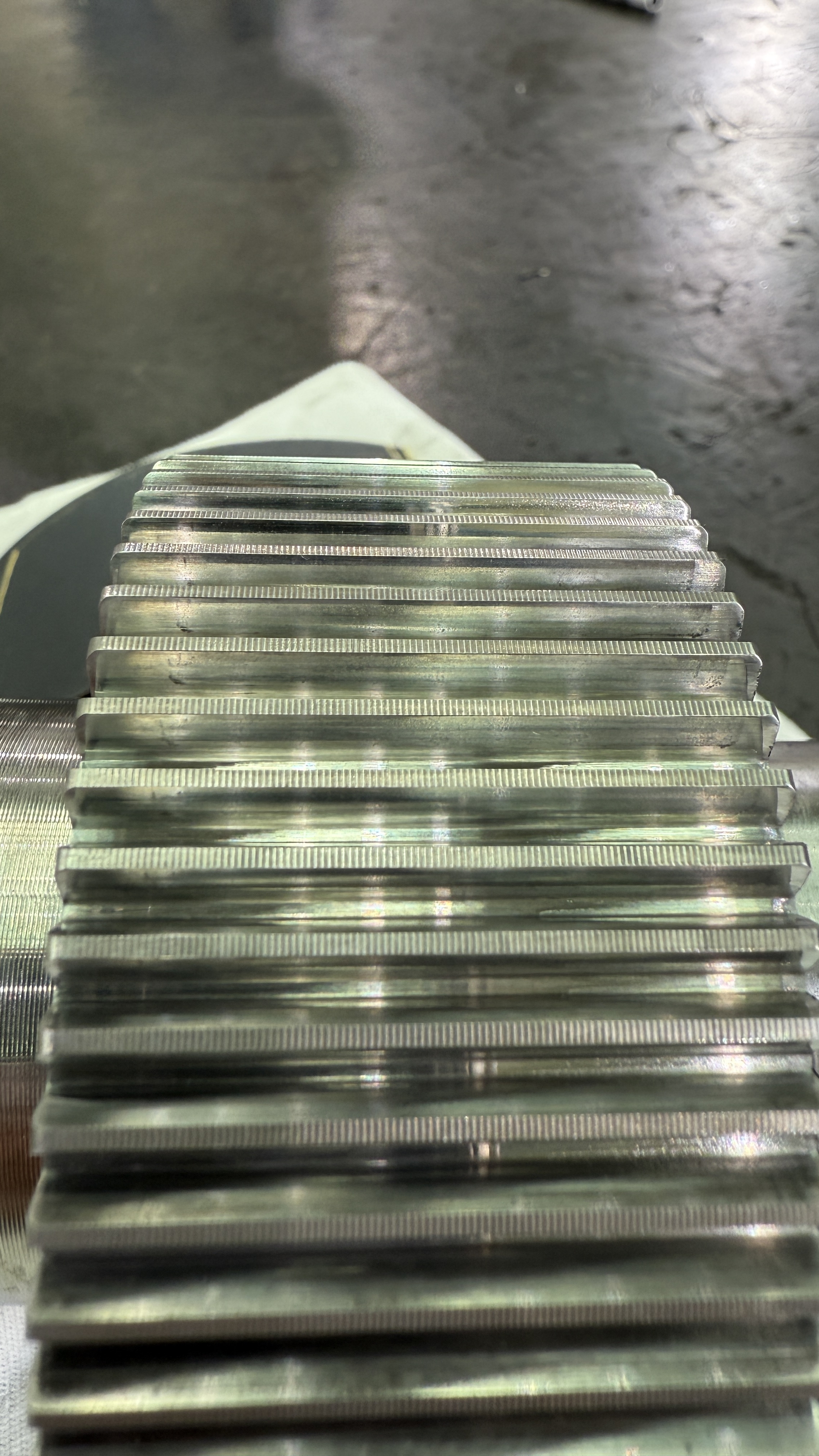

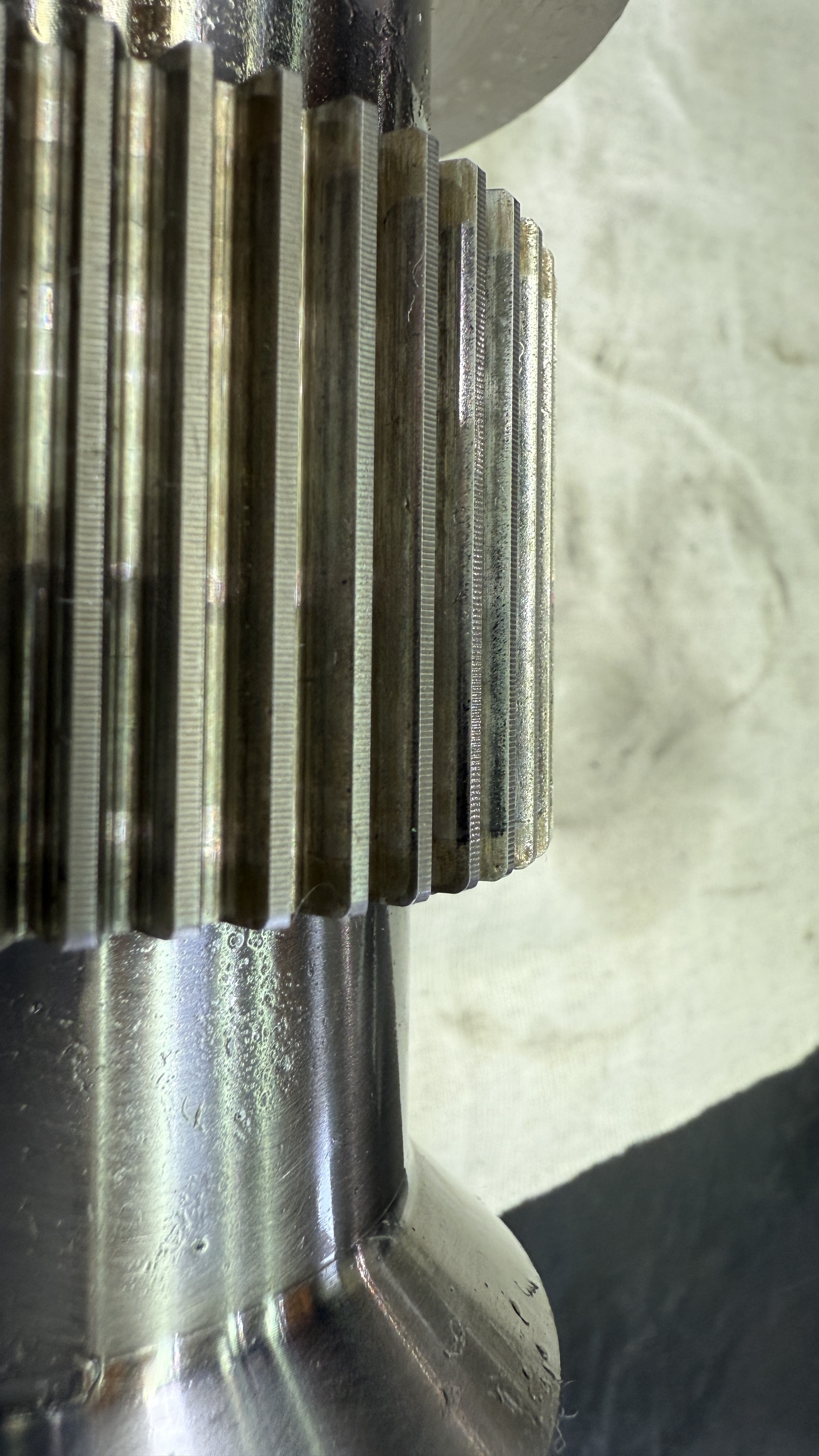

Abraision

Gear abrasion refers to the wear and tear on gear teeth caused by friction and the presence of hard particles between them. This can result in scratches, grooves, or even material loss on the gear surfaces. The severity of abrasion can range from mild, with fine scratches, to moderate, where machining marks are removed, or severe, leading to material loss and potential failure.

Causes of Gear Abrasion:

Contaminants in Lubricant:

Hard particles like sand, scale, rust, machining chips, or wear debris can act as abrasives.

Hard Surface Contact:

When a hard surface gear mates with a softer one, the hard surface can abrade the softer surface.

Wear Debris:

Fragments of worn-out gear teeth can also act as abrasives, causing further wear.

External Hard Particles:

Dirt, dust, and other hard particles can also enter the gear mesh and cause abrasion.

Types of Abrasion:

Two-body abrasion: Occurs when a hard particle is embedded in one surface and drags across another.

Three-body abrasion: Occurs when a hard particle moves between two surfaces.

Signs of Gear Abrasion:

Scratches or grooves on gear teeth: These are often oriented in the direction of sliding.

Material loss: Can lead to changes in gear geometry and functionality.

Micropitting: Small pits on gear surfaces, which can be a progressive failure mode.

Increased vibration or noise: As the gears wear and their alignment changes.

Prevention and Mitigation:

Proper Lubrication:

Using a clean, high-quality lubricant and ensuring regular lubricant changes can help reduce the presence of contaminants.

Material Selection:

Choosing appropriate materials for gears based on their application and wear resistance can help minimize abrasion.

Regular Maintenance:

Inspecting gears regularly for signs of wear and addressing any issues promptly can prevent further damage.

Filtration:

Using effective filtration systems to remove contaminants from the lubricant can reduce abrasive wear.

Cavitation Gear

Cavitation : Micro Jet Bubble