What is Honing???

Honing machines are metal abrading tools and the honing process utilizing hard tooling or honing stones and perishable abrasives stones for the correction of

Diameter

Shape

Surface finish

Positional tolerances of bores

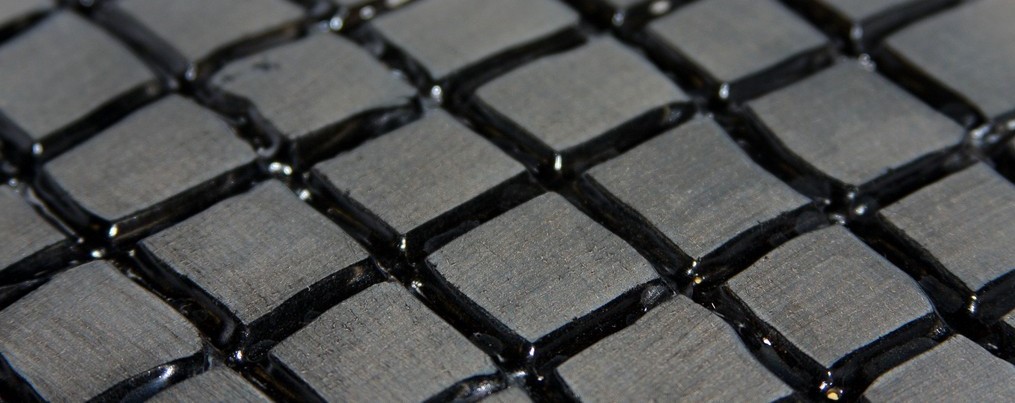

The honing process was developed to allow for perfection of bore geometry, size control, final surface finish and surface structuring. Lapmaster can help you learn the honing process that can provid the final sizing and creates the desired finish pattern on the interior of tubing or cylinder bores. Finishing is accomplished by expanding abrasive stones of suitable grit and grade against the work surface. The stones are rotated and reciprocated in the part with hone abrasive under controlled pressure. Combining rotation and reciprocation produces a cross-hatch pattern in the surface of the part being honed.

Why use a Lapmaster honing machine?

Lapmaster can provide a cost effective honing machining method for:

Removing stock

Generating exacting

Bore tolerances

Bore polishing

Finishing bores of almost any material such a: sprayed coatings, CGI, Ceramics, etc.

Define The Honing Process:

The honing process provides the final sizing and creates the desired finish pattern on the interior of tubing or cylinder bores. Finishing is accomplished by expanding abrasive stones of suitable grit and grade against the work surface. The stones are rotated and reciprocated in the part with hone abrasive under controlled pressure. Combining rotation and reciprocation produces a cross-hatch pattern in the surface of the part being honed.

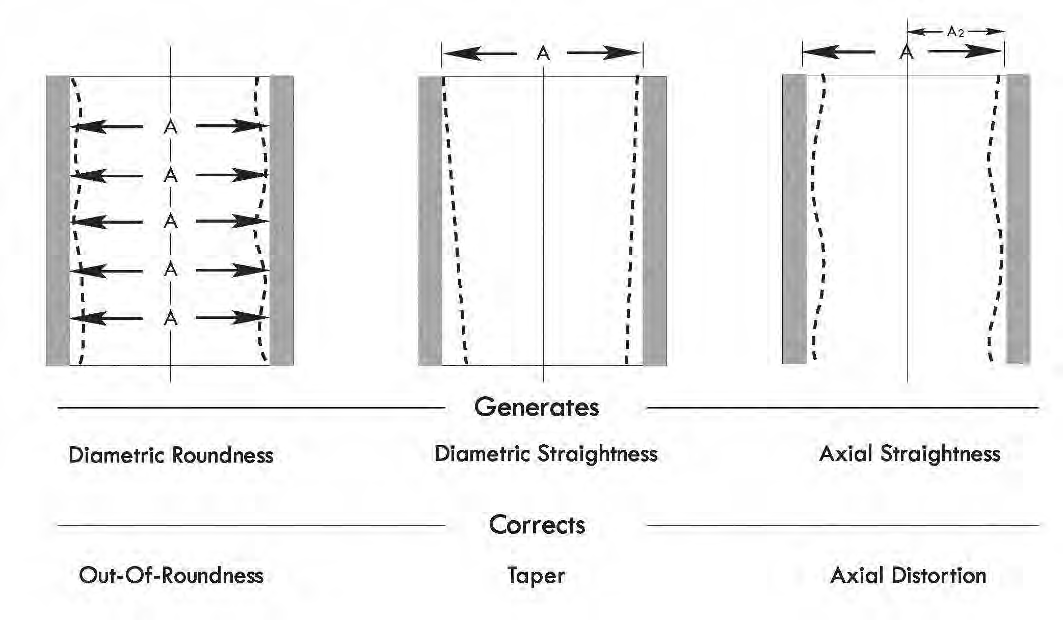

Lapmaster Honing Machines Perform Three Operations

First, it is a stock removal process (vertical honing machine) which takes out ruptured metal and reaches base metal.

Second, a finish pattern is generated to provide the best possible surface for promoting optimum lubricating conditions.

Third, honing stones assures extremely accurate straightness, roundness and size of the cylindrical surface.

What is honing?

What is single pass honing machine?

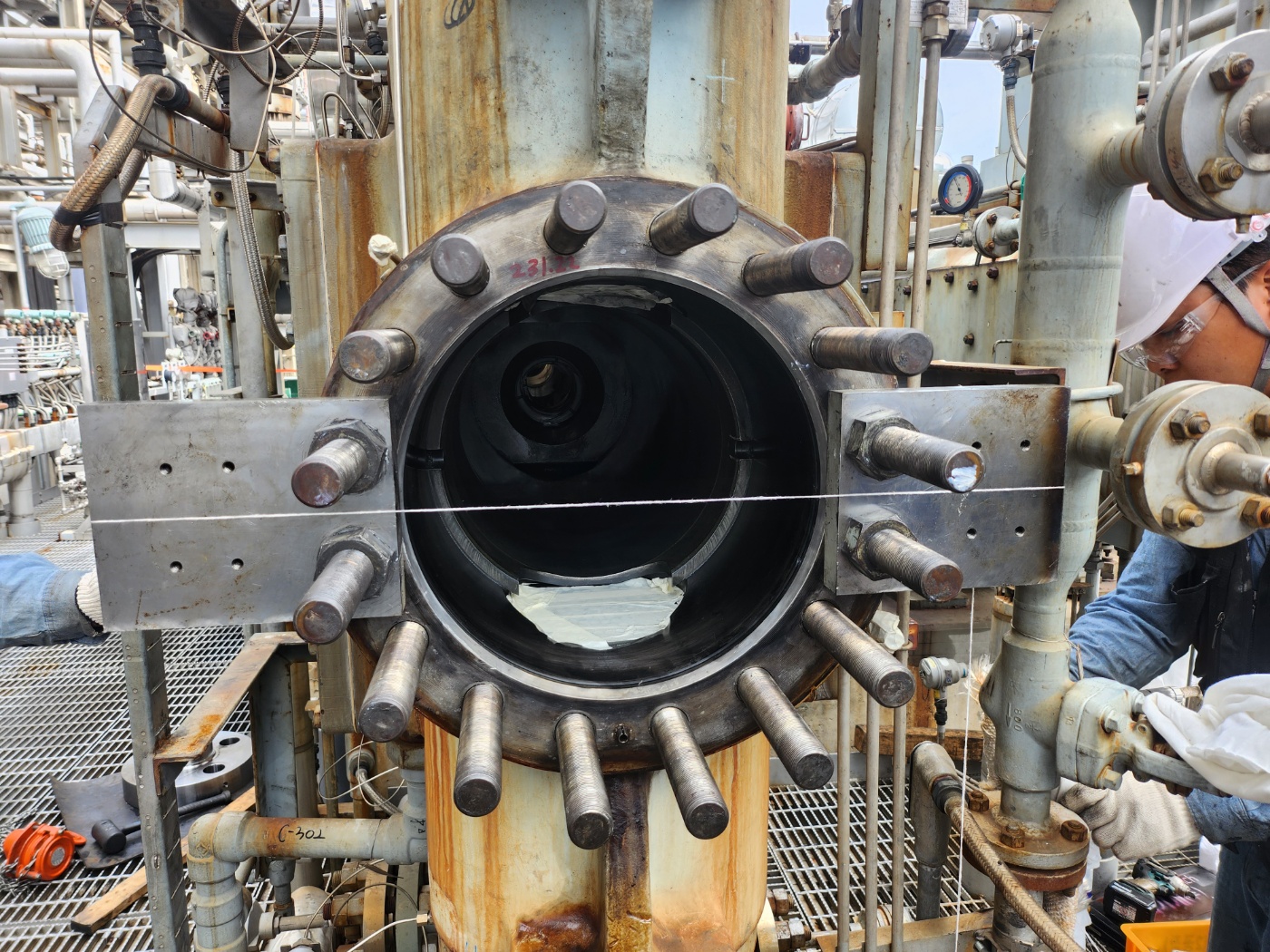

Single pass honing is done with a diamond abrasive, boring bar type honing tool. This type of honing tool produces a straight, round, and un-tapered bore in one pass of the tool through the part. Single pass honing is ideally suited for honing engine crank and cam bores. Since size is achieved in one pass, there is no crosshatch pattern in the finished part. The adjustable single pass tool expands the hone stones with a cone similar to standard tooling. However, the stones are not expanded and retracted as with conventional honing. The stones are only expanded to achieve size. The other difference is the hone tool is longer than standard tooling and the super abrasive coat the length of the tool. The single pass hone is tapered for about seven inches and has a final size section of 2.5 inches. See the photograph on the next page. The single pass tool has no in-process hone expansion, the machine must be stopped to adjust the tool.

When to Choose Lapmaster Single-Pass Honing Tooling?

Single-Pass honing machines, also called Bore Finishing, is selected for a variety of applications that have special needs involving honed cavities:

Small diameter honing tool machine (normally within 2”)

Honing tools for High-production quantities

Proper honing tools can reduce the cost per part

Reduced down-time for CNC honing tool change-over

Repeatable accuracy for dimensional tolerances such as bore size, roundness, surface finish

Only super-abrasive materials (Diamond and CBN) are used for the Single-Pass processing

A high rate/volume of coolant is needed to constantly remove the chips from the honing area

Oil or water-base coolants may be used for Single Pass honing, though oil is the most common

Single Pass honing process islimited to the types and volumes of material that can be removed. Specifically, the size and volume of chips removed must be no greater than there is clearance between the super-abrasive grits on the tool sleeve. As such, the Single Pass honing process is best suited for honing operations that produce a relatively small amount of chips, such as interrupted or short length bores. It is most successful (but not limited to) in honing cast iron and powdered metals.

Applications that feature a long length of material to be honed, small quantities and/or requiring a lot of material to be removed, are not the best suited parts for Single Pass honing. Rather, they may be best served using conventional Stroke Honing. In many cases, conventional Stroke Honing can also provide excellent dimensional geometry for these types of applications.